Compact Stationary Concrete Batching Plant

| Model | KSC 20 | KSC 25 | KSC 30 | KSC 45 | KSC 60 |

|---|---|---|---|---|---|

| Output capacity | 20 M3/Hr. | 25 M3/Hr. | 30 M3/Hr. | 45 M3/Hr. | 60 M3/Hr. |

| Plant assembly | Whole assemble on single chassis | ||||

| Mixer type | Turbo pan type mixer/twin shaft mixer | ||||

| Main reduction gear | Imported planetary gear box | ||||

| Main mixer drive | 20 HP | 25 HP | 30 HP | 40 HP | 50 HP |

| Material storage system | 2 × 2 cross bin feeder | ||||

| Material storage capacity | 14 M3 | 14 M3 | 20 M3 | 25 M3 | 30 M3 |

| Material weighing system | Digital load cell based weighing system | ||||

| Material feeding system | Through inclined belt conveyor | ||||

| Cement feeding system | Through inclined screw conveyor | ||||

| Water weighing system | Digital load cell based weighing of water in separate tank | ||||

| Admixture dozing system | Digital load cell based auto admixture dozing system | ||||

| Control panel | Fully automatic PLC based control panel | ||||

| Control cabin | Provided | ||||

| Concrete discharge height | 4.2 meter from the ground level | ||||

| Total connected power | 48 HP | 53 HP | 63 HP | 77 HP | 98 HP |

| Suggested DG Set | 62 KVA | 62 KVA | 82 KVA | 100 KVA | 125 KVA |

Mobile Concrete Batching Plant (KFP Series)

| Model | KFP 20 | KFP 25 | KFP 30 | KFP 45 | |||

|---|---|---|---|---|---|---|---|

| Output capacity | 20 M3/Hr. | 25 M3/Hr. | 30 M3/Hr. | 45 M3/Hr. | |||

| Plant assembly | Whole plant assembly is on wheel mounted single chassis | ||||||

| Mixer type | Pan type mixer / planetary mixer / Twin Shaft mixer | ||||||

| Main mixer drive | 20 HP | 25 HP | 30 HP | 40 HP | |||

| Material storage system | 2 × 2 cross bin feeder | ||||||

| Material storage capacity | 12 M3/Hr. | 12 M3/Hr. | 14 M3/Hr. | 20 M3/Hr. | |||

| Material weighing system | Digital load cell based weighing of aggregates, Cement, water and additive | ||||||

| Cement feeding system | Through inclined screw conveyor | ||||||

| Mobility arrangement | Provided along with tow bar facility | ||||||

| Control panel | PLC based control panel with internal cabling | ||||||

| Total connected power | 45 HP | 53 HP | 58 HP | 79 HP | |||

| Suggested DG Set | 50 KVA | 62 KVA | 82 KVA | 100 KVA | |||

| Concrete discharge height | 2.1 meter from the ground level | ||||||

Mobile Concrete Batching Plant with Reversible Drum Type Mixer (KRM Series)

| Model | KRM 15 | KRM 20 | KRM 30 | |

|---|---|---|---|---|

| Output capacity | 15 M3/Hr. | 20 M3/Hr. | 30 M3/Hr. | |

| Material storage capacity | 10 M3 | 12 M3 | 14 M3 | |

| Mixing and Discharge system | Forward rotation of drum mixes the material and reverse rotation of drum discharges the concrete | |||

| Material weighing system | Digital load cell based weighing of aggregates | |||

| Cement feeding system | Through inclined screw conveyor | |||

| Water feeding system | Timer based accurate water feeding system | |||

| Control panel | Fully automatic PLC based control panel | |||

| Pneumatic wheels | 2 nos | 2 nos | 4 nos | |

| Water tank capacity | 200 Liters | 250 Liters | 300 Liters | |

| Total connected power | 25 HP | 30 HP | 43 HP | |

| Total connected power | 40 KVA | 50 KVA | 62 KVA | |

| Concrete discharge height | 1.2 meter from GL | 1.5 meter from GL | 1.7 meter from GL | |

Concrete Road / Canal Paver Finishers

| Particulars | Specifications |

|---|---|

| Available width of the pavers | Starts from 3 Mtr and available up to 15 Mtr width |

| Prime Mover | |

| Drive End Panel | 5 HP Geared motor |

| Vibratory Cylinder | 5 HP Geared motor |

| Bogle RH & LH | 1 HP × 1 HP electrical geared motor |

| Vibratory Motor | 1HP. |

| Traction System | |

| Traction Drive | Two electrically Driven double flanged bogie wheels |

| Traction Speed | 0 – 22 RPM |

| Extra long screw Augur with harden flights for durability | |

| Shock protections | |

| Overload protections | |

| Adjustable carriage movement with variable speed drive | |

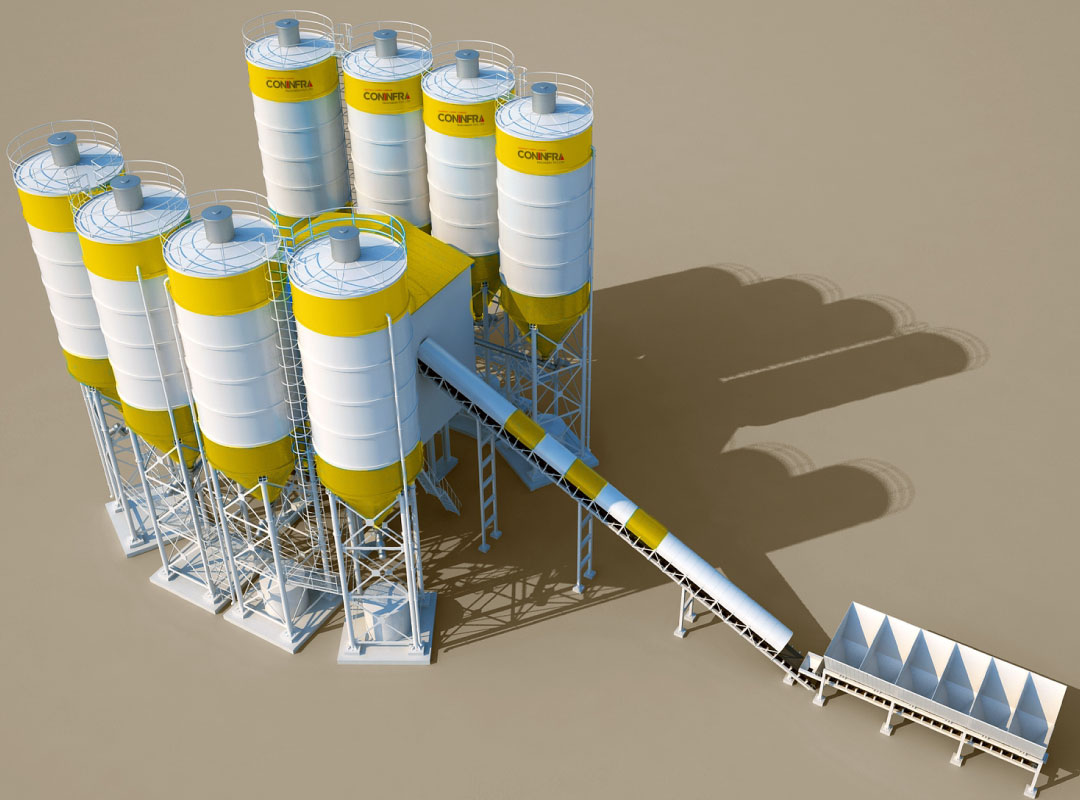

Horizontal Stationary Concrete Batching Plant

| Model | Coninfra 0.35 | Coninfra 0.50 | Coninfra 0.75 | Coninfra 1.0 | Coninfra 1.25 | Coninfra 2.00 | Coninfra 3.00 |

|---|---|---|---|---|---|---|---|

| Output capacity | 20 M3/Hr. | 30 M3/Hr. | 45 M3/Hr. | 60 M3/Hr. | 75 M3/Hr. | 90 M3/Hr. | 120 M3/Hr. |

| Mixer unit | Turbo pan type mixer/twin shaft mixer | ||||||

| Mixer type | Imported planetary Reduction gear box | ||||||

| Main drive/electrical motor | 20 HP | 30 HP | 40 HP | 50 HP | 60 HP | 50 HP×2 nos | 50 HP×2 nos |

| Material storage unit | 20 × 2 cross bin | In line four bin feeder | |||||

| Material storage capacity | 20 M3 | 30 M3 | 40 M3 | 60 M3 | 60 M3 | 90 M3 | 100 M3 |

| Material weighing system | Digital load cell based weighing material | ||||||

| Batch feeding system | Through inclined belt conveyor/inclined skip bucket | ||||||

| Cement feeding system | Through screw conveyor | ||||||

| Water weighing system | Digital load cell based weighing of water in separate tank | ||||||

| Admixture dozing system | Digital load cell based auto admixture dozing system | ||||||

| Control panel | Fully automatic PLC based control panel | ||||||

| Control Cabin | Provided | ||||||

| Concrete discharge height | 4.0 meter from the ground level | ||||||

| Total connected power | 52 HP | 74 HP | 87 HP | 120 HP | 145 HP | 200 HP | 275 HP |

| Suggested DG Set | 62 KVA | 82 KVA | 125 KVA | 160 KVA | 200 KVA | 300 KVA | 400 KVA |

Mobile Concrete Batching Plant (KMP Series)

| Model | KMP 15 | KMP 18 | KMP 24 | KMP 30 |

|---|---|---|---|---|

| Output capacity | 15 M3/Hr. | 18 M3/Hr. | 24 M3/Hr. | 30 M3/Hr. |

| Plant assembly | Whole plant assembly is on single chassis | |||

| Mixer type | Turbo Pan type mixer with spring backed arms | |||

| Material storage capacity | 10 M3 | 10 M3 | 12 M3 | 12 M3 |

| Material weighing system | Digital load cell based weighing of aggregates, Cement, water seprately | |||

| Cement feeding system | Through inclined screw conveyor | |||

| Mobility arrangement | Provided along with tow bar facility | |||

| Total connected power | 30 HP | 35 HP | 40 HP | 45 HP |

| Suggested DG Set | 40 KVA | 40 KVA | 50 KVA | 62 KVA |

| Concrete discharge height | 1 meter from the ground level | |||

Mobile Batching Machine Diesel Engine Operated (KMB Series)

| Model | KMB 800 DI | KMB 1050 DI |

|---|---|---|

| Output capacity / Hour | 10-12 M3 | 12-15 M3 |

| Mixing Type | Reversible drum tye mixer | |

| Mixing and Discharge of concrete | Forward rotation of drum mixes the material and reverse rotation of drum discharges the concrete | |

| Main drive of the mixer | 16 HP Air cooled diesel engine | 20 HP Air cooled diesel engine |

| Material weighing system | Digital load cell based weighing of material | |

| Water tank capacity | 200 liter | 250 liter |

| Water feeding system | Auto water dozing system | |

| Pneumatic tyres | 4 nos | 4 nos |

| Hydraulic tank capacity | 200 Liters | 250 Liters |

| Centralized lubrication system | Inbuilt Centralized lubrication system | |

| Tow bar facility | Yes | Yes |

| Control panel | Micro processor based control panel | |

| Hydraulic oil cooler | Yes | Yes |

| 12V DC battery | 80 AMP | 80 AMP |

10/7 Concrete Mixer

| Particulars | Specifications |

|---|---|

| Available width of the pavers | Starts from 3 Mtr and available up to 15 Mtr width |

| Prime Mover | |

| Drive End Panel | 5 HP Geared motor |

| Vibratory Cylinder | 5 HP Geared motor |

| Bogle RH & LH | 1 HP × 1 HP electrical geared motor |

| Vibratory Motor | 1HP. |

| Traction System | |

| Traction Drive | Two electrically Driven double flanged bogie wheels |

| Traction Speed | 0 – 22 RPM |

| Extra long screw Augur with harden flights for durability | |

| Shock protections | |

| Overload protections | |

| Adjustable carriage movement with variable speed drive | |

Screen Paver Finisher

| Available Width | Minimum width 3 Mtr and Maximum Width will be 6 Mtr. | |

|---|---|---|

| Cylindrical finishing rollers | Unique design as we provide two seperate cylindrical finishing rollers one at the front side and another at the back side so beter finishing is achieved more fo tis one can operate bth th rolers togather or stops any one voller 25 per requirement | |

| Augur arrangement | Full length augur is provided at the front side for spreading extra concrete equally on the both the ends of the slab to achieve even surface and more to this seperate drive is given with provision of forward and reverse rotation so one can operate it in either direction as per the requirement | |

| Drive rollers | Total four drive rollers are given where two rollers at each side is given with seperate drive for both the ends with provision of forward and reverse rotation so one can move the paver forward or reverse as per need and we also provide facility to turn on/off any side of the drive rollers which helps to move paver n curving areas of the slab | |

| Prime movers | Spreader augur | 3 hp electrical geared motors |

| Cyinderical finishing rollers | 5hp x 2 nos ele. Geared motors | |

| Drive rollers | 3hp x 2 nos ele. Geared motors | |

| Vibratory needles | 3hp x 5 nos ele. motors | |

| Total connected load (h.p) | 34 HP | |

| Suggested d.g. Set | 50 KVA | |

| Operator sitting | Adjustable seat with canopy provided at the top of the paver for the operator | |

| Control Panel | Mounted on the top of the paver with internal cabling and with wired remote control to operate the paver | |

| Mobility | Four mechanical type swivel jacks with solid tyre provided for height adjustment and for moving the paver at the each end of structure where tires are used to in or out the paver from panel area of the concrete slab | |

Installations Around the World

Technical Information

| Plan Type | CMPL 80 | CMPL 120 | CMPL 160 | CMPL 200 | CMPL 250 | CMPL 300 | CMPL 400 |

|---|---|---|---|---|---|---|---|

| Four Bin Feeder capacity (m3) | 8,10,12,15,20,m3 feeding width is up to 650 mm, dosing with frequency contrlling | ||||||

| Collecting Belt Width (mm) Length (mm) | 500 | 600 | 600 | 650 | 850 | 850 | 850 |

| Varies according to the number of silos | |||||||

| Inclined Belt Width (mm)01 | 500 | 600 | 600 | 650 | 850 | 850 | 850 |

| Dryer Diameter (m) Length (m) | 1.60 | 1.80 | 2.00 | 2.20 | 2.40 | 2.40 | 2.70 |

| 7.00 | 8.00 | 8.60 | 9.00 | 9.00 | 10.00 | 12.00 | |

| Sieving MAchine | |||||||

| 4,5,6 Decks | |||||||

| Hot Aggregate Silos Capacities (tons) | |||||||

| 4,5,6 Divisions | |||||||

| 9 | 20 | 20 | 25 | 25 | 30 | 30 | |

| Aggregate Weighing Capacities (kg) | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 |

| Filler Weighing Capacities (kg) | 150 | 200 | 200 | 250 | 300 | 400 | 500 |

| Bitumen Feeding Capacities (kg) | 6 | 6 | 10 | 10 | 15 | 15 | 20 |

| Mixer Capacities (kg) | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 |

| Automation | |||||||

| Coninfra Automation System | |||||||

| Bitumen – Fuel Tank Capacities (m3) | |||||||

| 20, 25, 30, 50, 60 | |||||||

| Thermal Oil System *1000 (Kcal/h) | 300 | 500 | 600 | 750 | 1000 | 1000 | 1000 |

| Electrical Heating | |||||||

| For all capacities, can be produced in variable capacities regarding to your requests. | |||||||

Frequently Asked Questions About Our Concrete Batching Plants

At Coninfra Machinery Pvt. Ltd., we offer stationary and mobile concrete batching plants to cater to the individual project requirements of our clients. In addition, we also provide bespoke equipment for large-scale construction projects. For any requirement pertaining to a specific scope of the project, you can consult our experts.

Our concrete batching plants are integrated with the latest control system to ensure error-free performance. A four bin aggregate feeder is equipped to provide a robust product. You also have the option to install customized accessories for increased performance.

Our mobile concrete mixing plants are easy to transport and need less space for installation. An automated control system enables you to control all the parameters to achieve high-quality concrete. Our product is available in standard size and a mini size to fit your unique requirements.

Absolutely. We provide on-demand and timely delivery for our construction equipment. Thanks to our qualified team of professionals who supervise the delivery of superior quality products.

Our Latest Articles

The Top Features to Look for in a Bitumen Sprayer Machine

Top Features of a Modern Batch Mixing Plant You Should Know

Top 10 Warning Signs Your Asphalt Drum Mix Plant Needs Repair

Reach out to Coninfra to receive innovative solutions for your business

+91 90999 41311

Social media