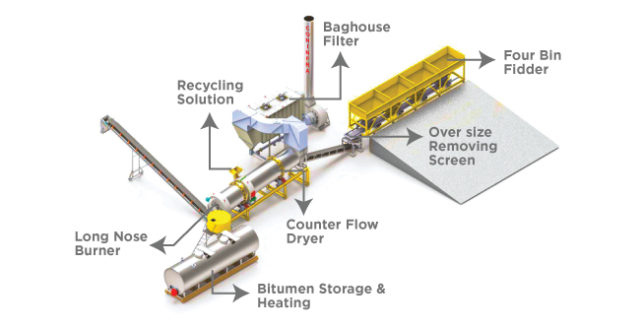

Components of Counter Flow Drum Mix Plant

In the realm of construction and infrastructure development, the demand for high-quality asphalt mix is paramount. To meet this demand efficiently, construction companies rely on advanced machinery such as counter flow drum mix plant. These plants, such as those provided by Coninfra Machinery Pvt Ltd, are designed to deliver superior performance and reliable output for asphalt production.

Understanding Counter Flow Drum Mix Plants

Counter flow drum mix plants are a cornerstone in the production of asphalt mixes. They operate on the principle of counter flow, where the aggregate and air flow in opposite directions. This design allows for efficient heating and mixing of materials, resulting in high-quality asphalt production.

Let’s delve into the key components that make up a counter flow drum mix plant and how each contributes to its functionality:

Four Bin Feeder

The four bin feeder is an essential component of the counter flow drum mix plant. It is responsible for accurately proportioning and feeding aggregates into the drying and mixing drum. These bins are equipped to handle different types and sizes of aggregates, ensuring versatility in asphalt mix production.

Oversize Removing Screen

The oversize removing screen plays a crucial role in ensuring the quality of the final asphalt mix. It efficiently removes oversized particles and debris from the aggregates before they enter the mixing drum. This process helps prevent clogging and ensures uniform mixing, resulting in a superior asphalt product.

Bag House Filter

Environmental considerations are paramount in modern construction practices. The bag house filter integrated into the counter flow drum mix plant helps mitigate air pollution by effectively capturing dust and particulate matter emitted during the asphalt production process. This ensures compliance with environmental regulations while maintaining air quality standards.

Recycling Solutions

Sustainability is a key focus in contemporary construction practices. Counter flow drum mix plants often incorporate recycling solutions that allow for the reuse of reclaimed asphalt pavement (RAP). By incorporating RAP into the asphalt mix, construction companies can reduce material wastage, conserve natural resources, and lower overall production costs.

Long Nose Burner

The long nose burner is a critical component responsible for heating the aggregates and bitumen to the desired temperature. Its design facilitates efficient combustion and heat transfer, ensuring optimal energy utilization and uniform heating throughout the mixing process. This results in consistent asphalt quality and enhanced productivity.

Counter Flow Dryer

At the heart of the counter flow drum mix plant lies the counter flow dryer. This component facilitates the drying of aggregates by directing them against the hot air flow in the opposite direction. This counter flow mechanism ensures thorough drying while minimizing heat loss, thereby enhancing energy efficiency and overall plant performance.

Bitumen Storage and Heating

Bitumen plays a pivotal role in asphalt production, serving as the binder that holds the aggregate together. Counter flow drum mix plants feature integrated bitumen storage and heating systems to ensure a continuous and consistent supply of heated bitumen throughout the production process. This ensures optimal mixing and binding of materials, resulting in durable and resilient asphalt mixes.

Counter flow drum mix plants offered by Coninfra Machinery Pvt Ltd represent a pinnacle of engineering excellence in asphalt production. By integrating advanced components such as the four bin feeder, oversize removing screen, bag house filter, recycling solutions, long nose burner, counter flow dryer, and bitumen storage and heating systems, these plants deliver unmatched performance, efficiency, and sustainability in asphalt production. As the construction industry continues to evolve, investing in state-of-the-art machinery like counter flow drum mix plants is essential for meeting the growing demands for high-quality infrastructure development while minimizing environmental impact.

To buy our premium quality Counter Flow Drum Mix Plant, contact us at sales@coninfra.in or call us at +91 90999 41311.