In the realm of road construction and infrastructure development, the efficiency and reliability of asphalt batch mix plants play a pivotal role. As the backbone of asphalt production, these plants must be optimized to ensure seamless operation and high-quality output. In this guide, we’ll delve into the essential components and operational aspects of asphalt batch mix plants, shedding light on how they contribute to maximizing production efficiency and quality.

Understanding Asphalt Batch Mix Plant:

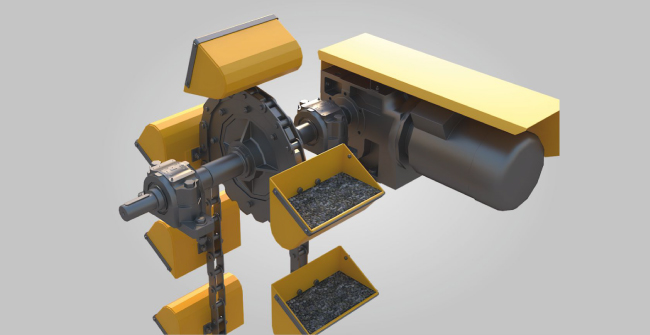

Asphalt batch mix plants are sophisticated facilities designed to blend various aggregates, bitumen, and other additives to produce asphalt mixtures of consistent quality. These plants operate in a batch process, where precise proportions of materials are mixed together in designated batches to meet specific project requirements.

Key Components of Asphalt Batch Mix Plants:

Cold Aggregate Feeder:

The cold aggregate feeder is the starting point of the asphalt production process. It stores and feeds different sizes of aggregates into the drying drum for further processing. The feeder is equipped with adjustable gates to control the flow of aggregates, ensuring accurate proportions in the mix.

Drying Drum:

The drying drum is a critical component where the aggregates undergo heating to remove moisture content. Proper drying of aggregates is essential to achieve the desired quality and consistency in the asphalt mix. The drying drum is equipped with burner systems that provide the necessary heat for the drying process.

Hot Elevator:

Once dried, the aggregates are lifted by the hot elevator and transferred to the vibrating screens for separation and grading. The hot elevator ensures the smooth and efficient transfer of aggregates from the drying drum to the mixing unit.

Mixing Unit:

The mixing unit is where the magic happens. It combines the dried aggregates with bitumen and other additives to create the final asphalt mix. The mixing unit consists of twin shaft paddle mixers or a pug mill, ensuring thorough blending of materials to achieve uniformity and consistency in the mix.

Bitumen Storage Tanks:

Bitumen storage tanks store the heated bitumen before it is injected into the mixing unit. These tanks are insulated to maintain the temperature of the bitumen and prevent it from solidifying. Proper storage and heating of bitumen are crucial to ensure optimal mixing and flow characteristics.

Optimizing Operation for Maximum Efficiency:

Precise Control Systems:

Modern batch mix plant are equipped with advanced control systems that offer precise control over the entire production process. Operators can monitor and adjust parameters such as aggregate flow, temperature, and mixing time to optimize production efficiency and quality.

Regular Maintenance:

Regular maintenance is key to ensuring the smooth operation of batch mix plants. Components such as burner systems, conveyor belts, and mixing units require periodic inspection and servicing to prevent downtime and maintain optimal performance.

Quality Assurance Practices:

Quality assurance practices are essential to producing asphalt mixes that meet industry standards and project specifications. Implementing quality control measures, such as batch testing and material analysis, helps identify any deviations or inconsistencies in the mix composition.

Environmental Compliance:

Adherence to environmental regulations is paramount in asphalt production. Asphalt batch mix plants must comply with emissions standards and pollution control measures to minimize environmental impact. Employing eco-friendly practices, such as using recycled materials and reducing energy consumption, further enhances sustainability.

Asphalt batch mix plants serve as the heartbeat of road construction projects, delivering high-quality asphalt mixes for durable and resilient roads. By understanding the components and operational aspects of these plants, construction companies can optimize production efficiency, ensure consistent quality, and minimize environmental impact.

At CONINFRA MACHINERY PVT. LTD, we are committed to providing cutting-edge asphalt batch mix plants that embody efficiency, reliability, and sustainability. Our state-of-the-art equipment integrates advanced technology and industry expertise to meet the evolving needs of the construction industry. With a focus on optimizing production and enhancing performance, we empower our clients to build the roads of tomorrow with confidence and precision. Choose Coninfra machinery for superior asphalt batch mix plants that drive progress and excellence in road construction.

To buy our premium quality asphalt batch mix plants, contact us at sales@coninfra.in or call us at +91 90999 41311.